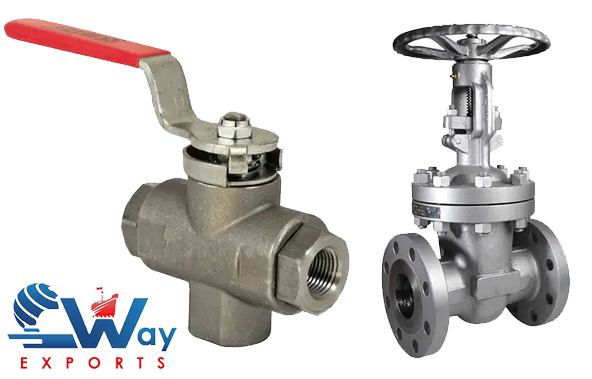

Ball Valves vs. Gate Valves: Pros and Cons

When it comes to industrial applications, choosing the right valve is crucial for optimal performance and efficiency. Two popular options that often come into consideration are ball valves and gate

What Are the Differences Between Seamless Steel Pipes and Welded Steel Pipes?

What Are the Differences Between Seamless Steel Pipes and Welded Steel Pipes? From the very first rudimentary pipeline used in 25000 BCE to today’s advanced piping system that transports water,

5 Factors to Consider Before Choosing Right Flange Type for Your Piping Project

5 Factors to Consider Before Choosing Right Flange Type for Your Piping Project Choosing an ideal flange for the piping project is key for operational reliability while optimizing the pricing and

Flanges and Types For Pipe Fittings

Flanges and Types for Pipe Fittings A flange is a mechanical joint system that offers a reliable way to connect pipes, valves, pumps, and other components to form a seal-proof piping

Indian Engineering Manufacturer Competing in the World

Indian Engineering Exporters Competing in the World There are millions of Engineering companies around the world with the most demand for mechanical and electrical engineering related products and services. Out of